Techno Sigma(TΣ)

Nitrogen injection automatic concentrator

EVAN-HEX

Nitrogen injection automatic concentrator「EVAN-HEX」

Automatic concentration stop at a specified level (volume) using a liquid level detection sensor, enabling precise control of the concentrated volume.

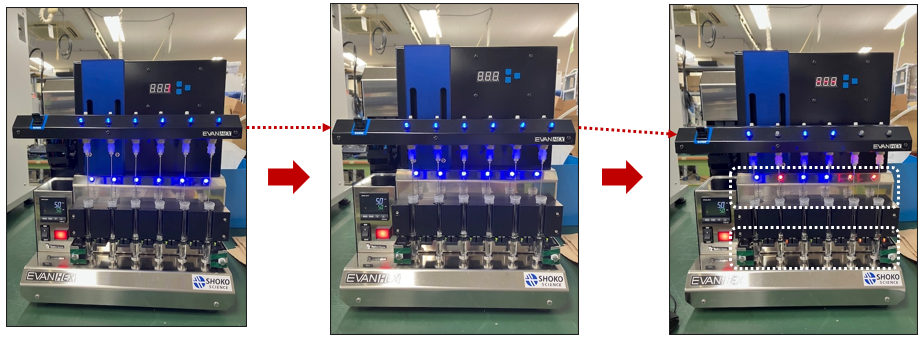

EVAN-HEX is a concentrator that uses nitrogen blow-down to evaporate and concentrate samples. As concentration proceeds over time, the spray nozzle automatically descends to maintain an optimal distance and efficiently concentrate the sample.

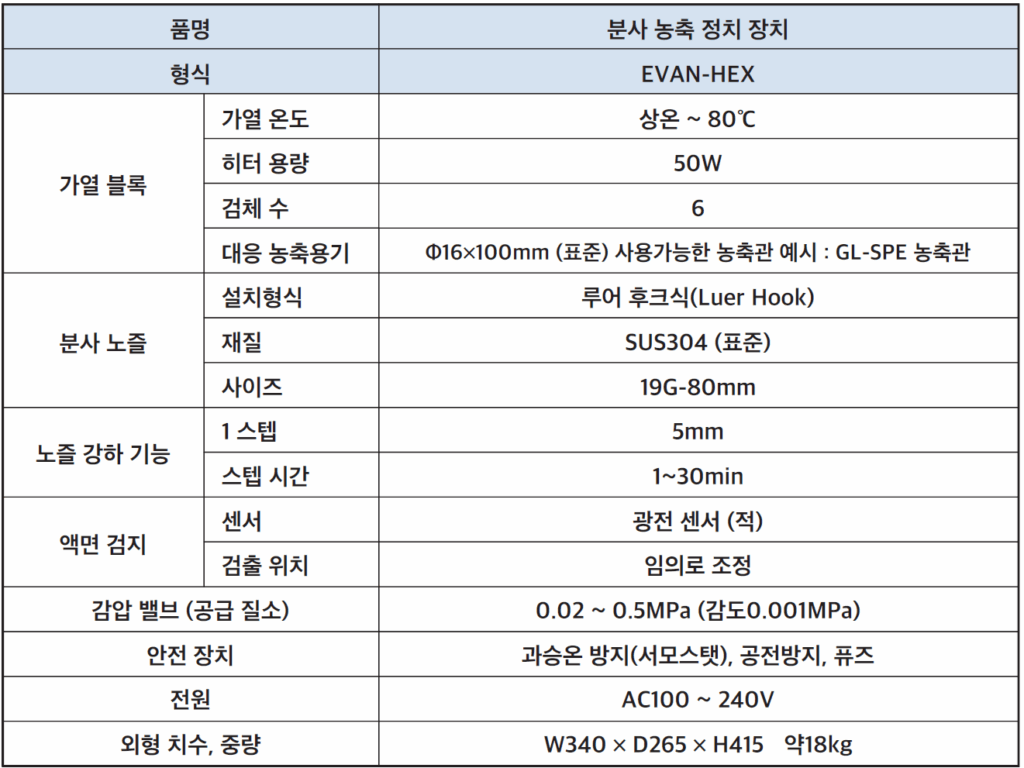

□ Heating Block

□ Spray Nozzle

□ Concentration position adjustment Screw

By adjusting the concentration position screw, you can set the desired concentration level and run the process automatically.

EVAN-HEX Features

① Automatic nozzle descent: 5 mm per 1–30 min (*operates when the heating block is running)

② The nozzles descend simultaneously, while the spray on/off control operates individually for each nozzle

③ Precise concentration is possible by adjusting the concentration position to achieve the desired final volume

As evaporation progresses, the spray nozzle automatically lowers. When the liquid level sensor no longer detects the liquid (i.e., the set level is reached), the indicator lamp turns red and concentration stops.

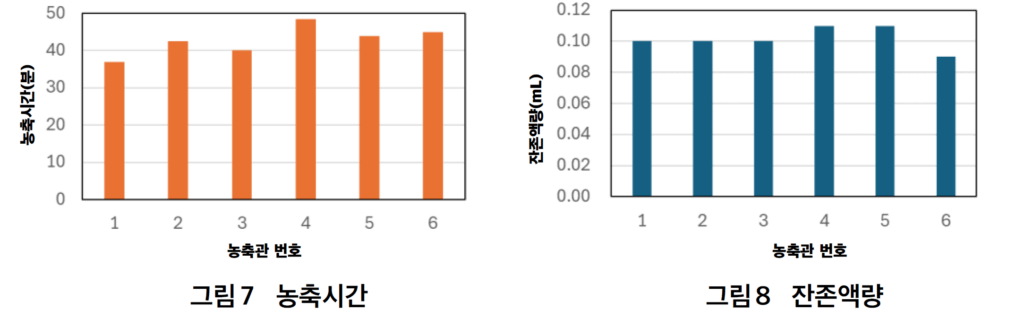

PFAS pretreatment concentration case (Kurita Industries)

※ PFAS sample concentration in compliance with Japanese Ministry of the Environment standards

■ Nitrogen injection flow rate: 1.2 mL/min

■ Concentration position adjustment: Set to a height of 0.1 mL

■ Heating block temperature: 40°C

■ Test solution: 5 mL of 0.1% ammonia in MeOH

■ Concentrator: GL Science GL-SPE glass concentrator (clear), 10 mL

■ Place the tip of the injection nozzle at the 8 mL mark on the concentrator and begin the concentration.

■ Descending speed: 1.5 mm/min

■ Measure the remaining liquid volume at the point where the nitrogen injection in each concentrator automatically stops.

(*栗田工業 KURITA WATER INDUSTRIES LTD.

The 85th Symposium of the Japan Society for Analytical Chemistry)

As a result of the analysis, the concentration time to the final liquid volume was 37 to 45 minutes, and the final liquid volume was in the range of 0.09 to 0.11 mL, so improvement in work efficiency could be expected.