VISCOMEDI (Sodium Polyacrylate)

VISCOMEDI(Sodium Polyacrylate)

Partially neutralized polyacrylic acid - adhesive for hydrogel formulations

About VISCOMEDI

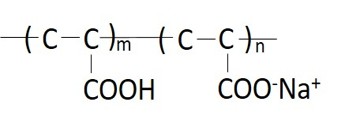

「 VISCOMEDI Structure 」

■ Product Name : VISCOMEDI

■ Chemical Name: Sodium Polyacrylate

■ Japanese Standard Name: Partially Neutralized Polyacrylic Acid

■ Molecular Weight: Undisclosed

■ CAS No. : 9033-79-8

VISCOMEDI (partially neutralized polyacrylic acid) is a water-soluble polymer produced by polymerizing acrylic acid.

Mixtures of partially neutralized polyacrylic acid have long been used as wet compress materials and as formulation additives for cooling sheets. Due to the linear arrangement of its molecular structure, it exhibits spinnability, and because it contains a large number of carboxyl groups (-COOH) within the molecule, it can be formulated into an elastic hydrogel by using crosslinkers such as trivalent metal ions.

Note: This product is different from crosslinked superabsorbent polymers (SAP) or microgel products.

VISCOMEDI Product types

Available in Three Grades by Degree of Neutralization

Viscosity 1) | pH 2) | Features | |

P-700 | 500 ~ 650 | 6.2 ~ 6.8 | General-purpose grade |

P-800 | 450 ~ 600 | 5.5 ~ 6.1 | Suitable for formulations requiring lower pH and higher tack |

P-600 | 500 ~ 650 | 7.0 ~ 7.4 | Suitable for stable alkaline-compound formulations |

1) Measured in 0.2% aqueous solution at 30 rpm, 20°C, using a B-type viscometer(mPa・s)

2) pH of a 0.2% aqueous solution

VISCOMEDI Features

■ Adhesiveness

■ Water Solubility

■ Thickening

■ Anionic (COO-)

When partially neutralized polyacrylic acid dissolves in water, sodium ions on the pendant carboxyl groups dissociate, generating anionic sites. Electrostatic repulsion between these anions causes the polymer chains to extend into linear structures, resulting in thickening. The aqueous solution is a non-Newtonian fluid and does not exhibit thixotropy.

With a very high molecular weight in the millions, the resulting aqueous solution forms a strongly mucilaginous (gel-like) texture.

Partially neutralized polyacrylic acid functions in end products as an “adhesive,” “moisture-retention agent,” “binder,” and “thickener.” By leveraging these functions, it can be applied to the following uses:

■ Wet compresses (pharmaceutical use)

■ Cooling sheets (consumer/industrial products)

■ Face masks (cosmetics)

■ General consumer goods (miscellaneous items)

VISCOMEDI Application

After dispersing partially neutralized polyacrylic acid in a humectant such as glycerin, it can be mixed with water, an aluminum compound as a crosslinking agent, and an organic acid to obtain the raw material for a “hydrated gel” (sol state). As the crosslinking reaction proceeds, the material transitions into a gel form. This technology can be applied to pharmaceutical patches, cooling sheets, and medical devices. In this hydrated gel, partially neutralized polyacrylic acid plays the following roles:

Provides tackiness (adhesion) to the gel.

Provides shape retention (formability).

Retains water or solvents within the gel.

Hydrated gels can also be produced using other water-soluble polymers (such as sodium alginate or carrageenan), but these gels tend to tear easily and lack tackiness. In contrast, gels made with partially neutralized polyacrylic acid are elastic, resist tearing even when stretched, and provide tackiness.

VISCOMEDI Product Unit

■ Packing Unit : 20kg/Bag

■ Sample Unit : 100g/Bag

Precautions when handling VISCOMEDI products

▶ Please be sure to read the MSDS (Material Safety Data Sheet) before handling this product.

▶ Please determine suitability for each intended application at your own discretion, referring to the examples of use described above.

▶ For pharmaceutical applications, use is limited to topical and transdermal routes only.

Please refrain from applying the product to damaged skin formulations.

▶ Values such as physicochemical properties are not guaranteed specifications.

▶ As this is a water-soluble polymer, please take care to prevent moisture absorption during storage.

(We recommend storing the product unopened in a desiccator or similar dry environment.)

▶ More detailed documentation is available. If you need any additional information, please feel free to contact us at any time.