Spheryx - xSight

Spheryx xSight, a leader in Total Holographic Characterization (THC) technology

Technology of Total Holographic Characterization(THC)

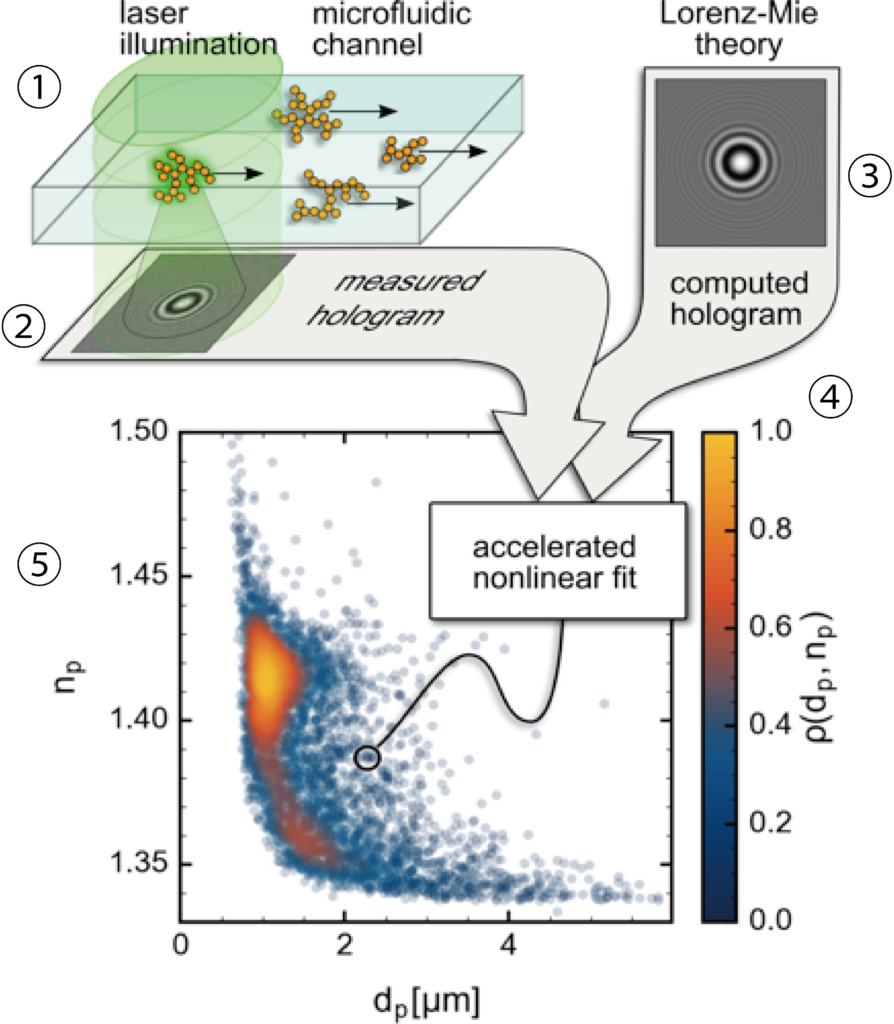

Total Holographic Characterization (THC) measures the size and refractive index of each particle based on the unique holographic characteristics of each particle, using Lorenz-Mie theory. Based on these measurements, the particle type is calculated and the concentration is calculated by dividing the measured value by the measured volume.

This technology enables non-destructive quantitative analysis of suspended particles, such as colloidal microspheres, emulsion droplets, or irregular particles (impurities) including aggregates and agglomerates, with high precision and reliability. Spheryx xSight facilitates prediction of the behavior of particulate suspensions for formulation optimization, quality assurance screening, manufacturing process control, and sample analysis.

Spheryx xSight is primarily used for the quantification of protein aggregates in biopharmaceuticals and the quantification of large particles (impurities) in CMP slurries.

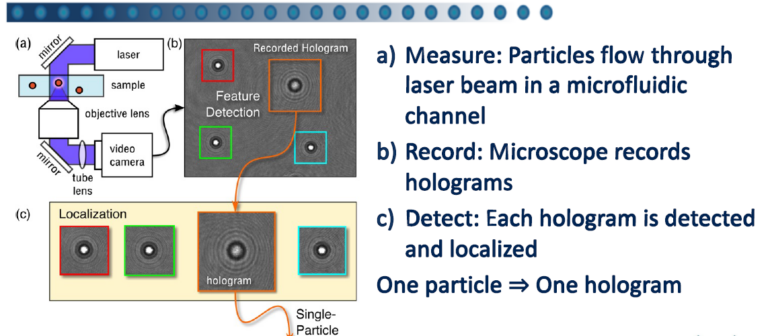

(THC technology schematic)

Measurement method

① The sample loaded into the sample introduction section moves through a microfluidic channel to the measurement section where the laser is irradiated.

② The interference pattern (hologram) of each particle is recorded.

③ The measurement results are compared and analyzed with scattering theory (Lorenz-Mie theory).

④ Through this comparative analysis, the following data is obtained for each particle:

◦ Particle radius

◦ Refractive index

◦ Symmetry

◦ Homogeneity

⑤ The analysis results are displayed in aggregate.

The analysis results for each particle are displayed at each point.

The number of analyzed holograms directly corresponds to the number of particles, allowing the number of particles to be calculated based on particle size.

Application ①: Quantification of protein aggregates in biopharmaceuticals

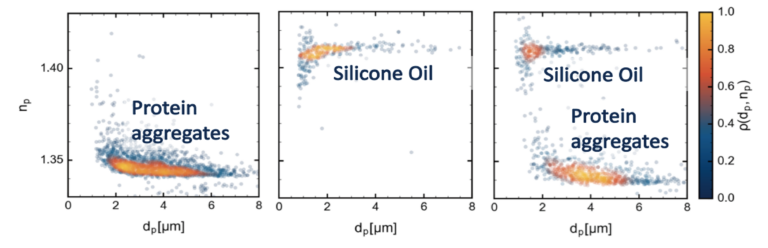

This is an example of measuring protein aggregates, a challenge in biopharmaceutical development.

xSight can identify proteins and foreign substances (such as silicone oil) in the 0.5-10μm range, accurately determining particle size and particle concentration (number of particles/mL).

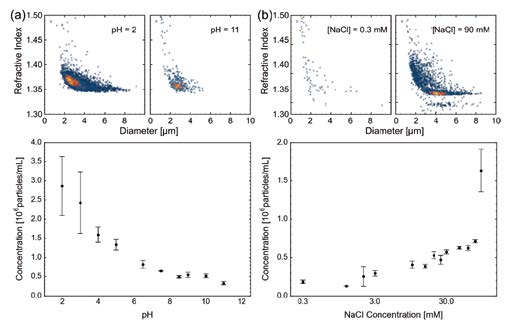

Application ②: Quantification of large particles in CMP slurry

CMP slurries used as semiconductor wafer polishing agents require management of large particles that can cause scratches. xSight can easily identify aggregate formation behavior based on differences in slurry dispersion.

Figure (a) below shows the results of aggregate particle concentration measurements based on pH differences, and (b) shows the results of measurements based on salt concentration (ionic strength).

Dispersion stability of trace components can be verified in a short period of time under various solution conditions.

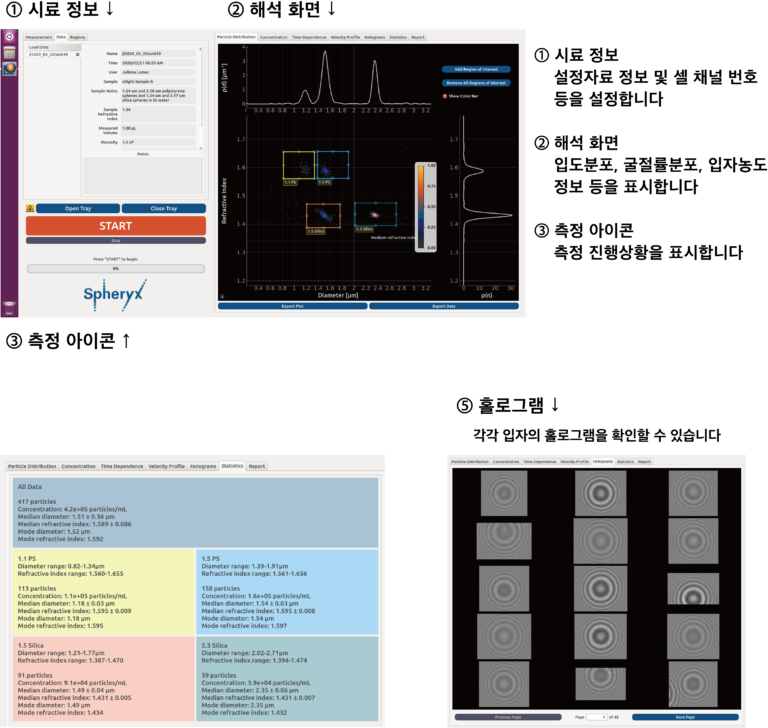

Control & Analysis Software

From measurement setup to interpretation, anyone can easily do it.

xSight Specification

<Xsight>

Measurement particle range | 0.5 ~ 10μm |

Measurement sensitive | 103 Particles/mL |

Sample Concentration | 104 ~ 107 Particles/mL |

Measurement Sample Volume | 25 ~ 35μL |

Measurement unit temperature | room temp. ~ 40℃ (± 0.3℃) |

Measurable sample viscosity | 1 ~ 20cP |

Solvent | Aqueous solvent (pH : 2 ~ 10) |

Operating temperature | 20~30℃ |

Size (L x W x H) | 560 x 216 x 305mm |

Weight | 24kg |

<Autosampler xStream>

Measurement particle range | 0.5 ~ 10μm |

Measurement sensitivity | 560 x 216 x 305mm |